What makes a bag fully waterproof?

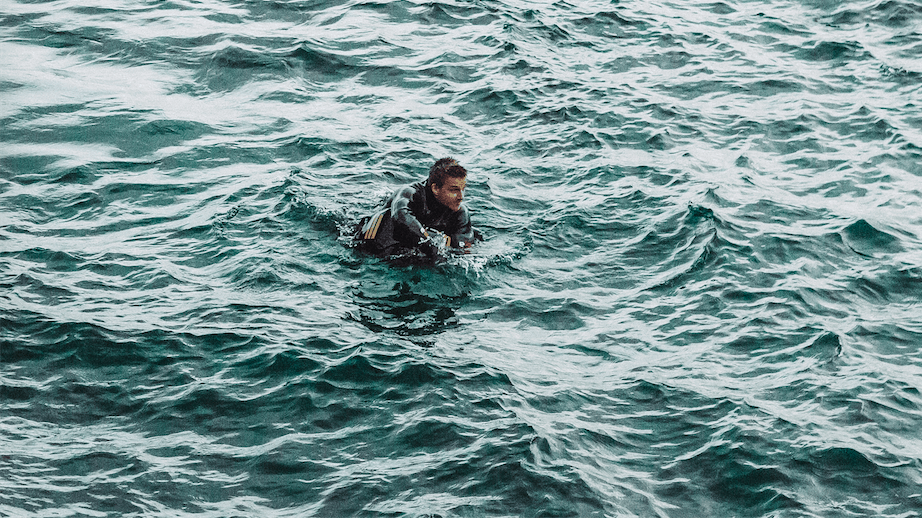

–Name: Jari Cennet Tammi

–Adventure: World’s Longest Swim Adventure

–What: Swim along the hole Mediterranean Sea.

–Where: Istanbul, Turkey to Cadiz, Spain.

–Start: 1st of October, 2024.

–Currently: Karaincirli beach, Turkey

–Total Distance: 10.000km

–Distance completed: 200km

–Duration: 10 Years

–Age: 66

–Bags used: 1x Pro Drybag 100L and 1x Pro Drybag 55L

–Tools: Multi-tool

–Total weight of the bags dragged behind: 59kg

Pro Drybag 100L – 36kg

Pro Drybag 55L – 23 kg.

Packed with tent, dryfood, storm kitchen, water, sleeping bag and other essential gear.

–Live Tracking: Link

–Facebook: Link

–Instagram: Link

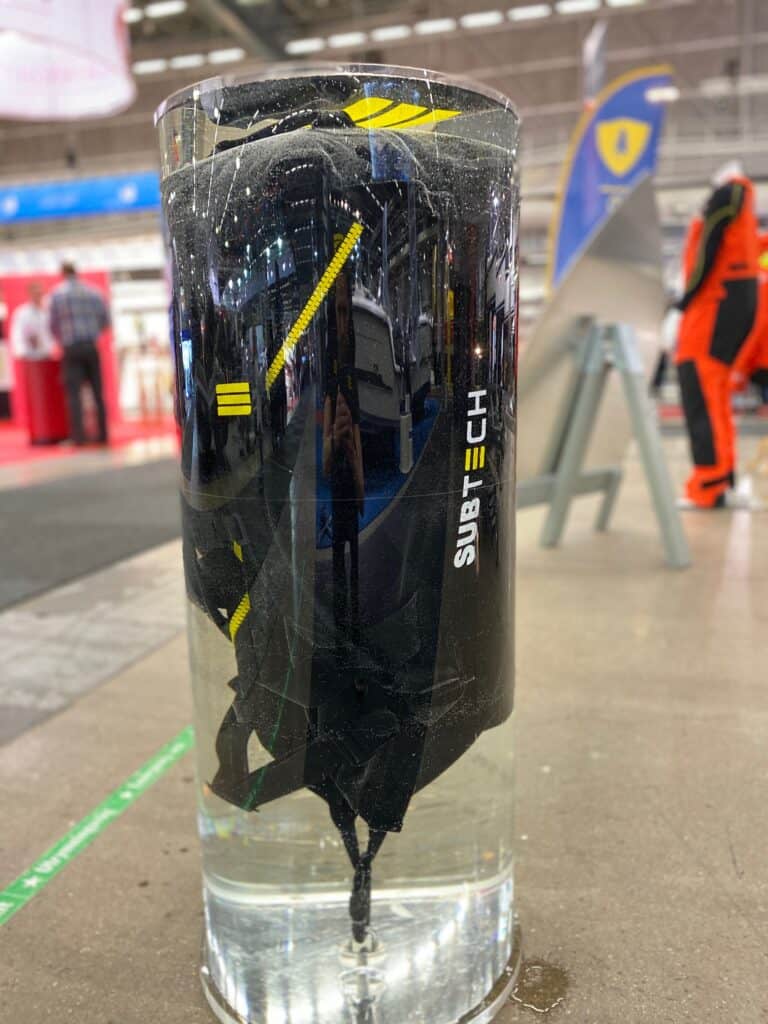

Bag: PRO DRYBAG 55L

Fabric: Hypalon

Size: 63x30x30 cm | 24.8×11.8×11.6 in

Weight: 1685 g / 60 oz

Zipper: YKK Aquaseal 10

Images: Victor Daggberg | Marcus Grip

Why are some bags waterproof, and others not? Knowing the difference between waterproof and water resistant might actually save you a few thousand dollars on your next journey. In order for a bag to be fully waterproof, there are a few essential things to be aware off. The first fundamental aspect is the fabric of the bag – we use hypalon which is the most advanced and durable material out on the market. It’s in fact the same material that the military use for their RIB boats. We also have an IP68 classification which means that the bag can withstand dust, dirt, sand and may also be submerged under water for an extensive period of time.

Most companies market their bags as ‘waterproof’ but can in real life only handle heavy rain for a shorter period of time and possibly be soaked by a wave or two. If you are planing an adventure and need to rely on that your equipment stay dry no matter how heavy the rain is, or how big waves will hit you during the whole trip, you will need to look for a IP68 rated bag. Often referred to as a “submersible bag” but in order to submerse the bag you need to vacuum seal the bag by removing all air before closing the airtight zipper. If you are looking for buoyancy you can easily do the opposite by closing the airtight zipper, making sure you got air inside the bag that will allow the bag to float even if it’s fully packed with an adult laying on top of it which is an invaluable asset if worst comes to worst on your adventure.

The next crucial thing is the zipper, a normal zipper would not last one day in the life of our water sport athletes, and definitely not their gear. We use the YKK Aquaseal 10 which is airtight and manufactured with the highest quality possible and pressure tested up to 500mbar / 7 psi. Furthermore, a completely waterproof zipper is substantially more robust than an average zipper and require some state-of-the-art engineering. Hence the heavy price increase if you compare watertight bags vs. submersible bags as the airtight zipper or drysuit zipper sometimes cost more to produce (the zipper by itself) than a complete watertight bag.

Next in line is the construction of the bag. As long as the bag is sewn with normal stitches, it does not matter how good the fabric is, nor how good the zipper is – it will still let water in. Instead, a special design that is completely airtight with no holes is required in order for the bag to be fully waterproof. We use a high frequency welding technique where the extremely durable hypalon fabric is welded together with the zipper to form a strong joint material.

Here you can check out our upcoming PRO DRYBAG 3.0 Series that is available to pre-order now for Special Launch Offer Price!

The Pro Drypack 30L is hereby listed in the world’s largest defense logistic database.

NATO STOCK NUMBER: 8465-64-002-2014

Key features:

✔️ Submersible down to 50m/165ft when deflated

✔️ Floats fully packed with a soldier on top when inflated

✔️ Air-tight zipper to protect electronic equipment

✔️ Oral inflator to inflate and deflate the bag quickly

✔️ Laser cut velcro internally to attach medkit pouches

✔️ External easy access pocket for Hypothermia kit

✔️ Optional fully customizable organization system

✔️ Removable straps for underwater transportation

✔️ Attachment points to secure the bag on to anything

✔️ Optional Inflation and Exhaust valves

✔️ Optional scuba tank to rise the bag from the bottom

Thanks to our team of extreme sports athletes, world record adventurers, professional units and partners that push the boundaries what is humanly possible with our bags, 365 days per year.

Providing us with invaluable feedback so we could develop the Pro Drypack 30L

Comments are closed for this article!